The client

Hydrostal pump based manufacturing based in West Yorkshire commission grw energy cost reduction to review all the key elements of the sites energy consumption and report findings for new energy legislation and green credentials .

Findings

Hi bay lighting was consuming 46 kilowatt of energy consumption across the site with offices using 12 kilowatt in energy . Power factor correction was lagging below recommend efficiency level due to Rotating machines and test bay hi power test rigs .

The power tariff and gas tariffs were above industry average for unit cost for this type of consumption and a review was considered to be undertaken.

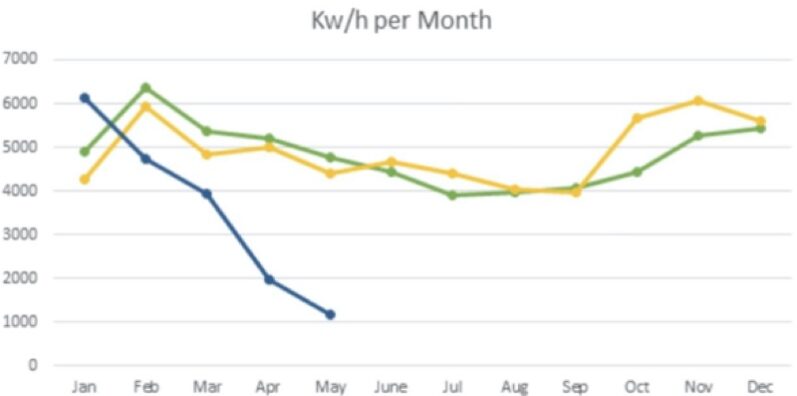

The roof was south facing and GRW decided to undertake a case study to off set the day time consumption against power generation using PV hi output technology panels.

Delivery

Full led lighting was implemented throughout the business with switching optimisation in all sections with 80% energy saving . Full 40 KW PV was positioned south facing in the roof with auto feed in demand with day time energy off set of 36% of the max day time consumption. Power factor correction and further tariff saving on gas and electric made the site overhaul demand savings of over 48% on day time consumption.

Feedback

“What result and what a team from the initial survey to the final handover. Great results great savings!”

Site managing director